- Home

- Products

- Certificates

- Cooperation

- About Us

- News

- Contact

Contact

+86 188 3213 4509

Contact

+86 188 3213 4509

Applications

Bared copper conductor is also known as copper stranded conductor. Specially suitable for application in:

● Overhead transmission system

● Overhead traction system

● Transformer earthing(occasionally)

● For grounding electrical systems where high conductivity and flexibility is required.

For any more information or advice please contact the office on 0086-18832134509 (WhatsApp/WeChat)

Details

Overview

Overview Stranded Bared Copper Conductor

Bare Copper conductors are primarily used for grounding purposes as specified in the National Electrical Code.Soft-drawn solid or stranded conductors, for use as grounding connections in circuits, and grounding for machinery or equipment. Hard-drawn conductors for overhead transmission and distribution lines, as grounding connections in circuits, and grounding for machinery or equipment.

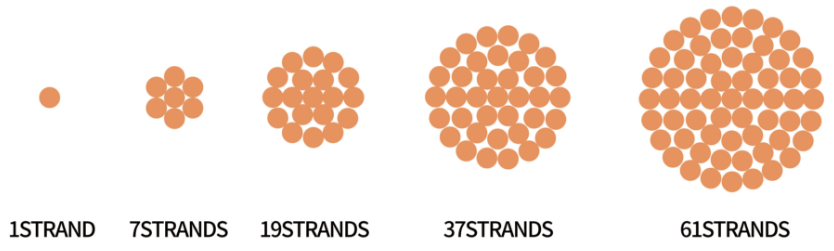

Construction

Conductor Sections

Conductor: Hard-drawn stranded Copper Wire

Standards

Basic design to EN13602/BS 7884/ASTM B8/JIS C 3105:1994/AS1746 standards.

Technical Data

| EN 60228(*if other standards are required, please contact with us) | |||||

| Nominal Cross Sectional Area | No. of Wires | Diameter of Wires | Diameter of Conductor | Nominal Weight | Maximum DC Resistance at 20℃ |

| mm² | mm | mm | kg/km | Ω/km | |

| 16 | 7 | 1.7 | 5.1 | 137 | 1.15 |

| 25 | 7 | 2.13 | 6.9 | 215 | 0.727 |

| 35 | 7 | 2.52 | 7.56 | 300 | 0.524 |

| 50 | 10 | 2.52 | 8.9 | 410 | 0.387 |

| 70 | 14 | 2.52 | 10.7 | 595 | 0.268 |

| 95 | 19 | 2.52 | 12.6 | 820 | 0.193 |

| 120 | 24 | 2.52 | 14.25 | 1040 | 0.153 |

| 150 | 30 | 2.52 | 15.75 | 1280 | 0.124 |

| 185 | 37 | 2.52 | 17.64 | 1600 | 0.0991 |

| 240 | 48 | 2.52 | 20.3 | 2100 | 0.0754 |

| 300 | 61 | 2.52 | 22.68 | 2700 | 0.0601 |

Bare stranded copper conductors are engineered from multiple twisted electrolytic copper wires, offering unmatched flexibility and conductivity for demanding electrical applications. Ideal for grounding, overhead power distribution, and industrial systems, these conductors meet ASTM B8, IEC 60228, and NEC 250 standards, ensuring safety and performance.

Material: 99.9% pure electrolytic copper (C11000/C10200), annealed for superior ductility.

Conductor Types:

Hard-Drawn: High tensile strength (350-500 MPa) for overhead power lines.

Soft-Drawn: Flexible design (200-300 MPa) for grounding and equipment earthing.

Sizes: 6 AWG to 1000 kcmil, customizable stranding (Class B, C, or custom patterns).

Low Resistivity: ≤0.01724 Ω·mm²/m at 20°C for efficient current transmission.

Corrosion Resistance: Bare copper surface ensures long-term durability in harsh environments.

Electrical Grounding Systems: Substation grounding grids, transformer earthing, and equipment bonding (NEC 250 compliant).

Overhead Power Transmission: High-voltage transmission lines, railway catenary systems, and renewable energy projects.

Industrial Use: Petrochemical plants, data centers, mining machinery, and solar/wind farm interconnections.

Certified Quality: ISO 9001 manufacturing with RoHS compliance and third-party test reports (conductivity, elongation).

Custom Solutions: CAD-supported prototyping for non-standard sizes or stranding configurations.

Global Logistics: FOB/CIF terms, 15-30 day lead time, and secure packaging (wooden reels/drums).

Competitive Pricing: Transparent quotes based on real-time LME copper prices and volume discounts.