- Home

- Products

- Certificates

- Cooperation

- About Us

- News

- Contact

Contact

+86 188 3213 4509

Contact

+86 188 3213 4509

Applications

N2XSY is a single core cable with a stranded copper conductor, XLPE insulation, copper wire screen with intermittent copper tape screen and PVC oversheath. If using PE oversheath, that is N2XS2Y. The cables are mainly used for:

● Indoors and in cable ducts

● Outdoors,underground

● In power supply stations

● Transformer stations

● Industrial Plants

Due to the good laying characteristic, this cable can also be installed in difficult line guideways.

The inner conducting layer between the conductor and the XLPE insulation and the firmly bonded outer conducting layer on the XLPE insulation assures a construction free of partial discharges with high operational reliabilities.

For any more information or advice please contact the office on 0086-18832134509 (WhatsApp/WeChat)

Details

Overview

Overview The N2XSY (medium cable)has a single core copper stranded class 2 conductor with cross-linked polyethylene(XLPE)insulation, copper wire screen with intermittent copper tape screen and PVC oversheath. If using PE oversheath, that is N2XS2Y. N2XSY cable is widely used for power distribution networks, transformer stations, switching blocks and power plants, including in the renewable energy sector, the N2XSY offers a low factor of dielectric loss and excellent insulation property of XLPE for high operational reliability. It should not be subjected to heavy mechanical or tensile strain. It can be manipulated and installed in ambient temperatures ranging between -5℃ and +70℃.

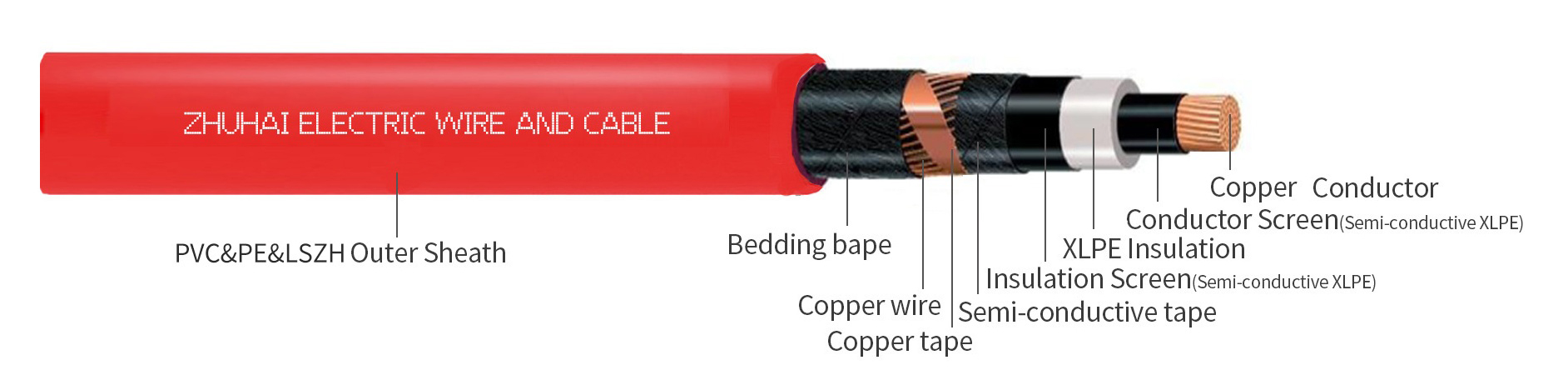

Descriptions:N2XSY Single Core MV Power Cable

Conductor:Copper, Class2,Circular compacted conductors

Conductor Screen: Non-metallic,semi-conducting compound

Insulation: Cross-linked polyethylene XLPE

Insulation Screen: Non-metallic,semi-conducting compound

Metallic Screen: Copper wire screen with intermittent copper tape screen

Outer Sheath: Polyvinyl Chloride PVC

Physical Properties

Operating Temperature: up to 70℃(PVC insulation); up to 90℃(XLPE insulation)

Temperature Range: -5℃(PVC or LSZH sheath); -20℃(PE sheath)

Short Circuit Temperature(5 seconds maximum duration): 140℃-160℃(PVC insulation);250℃(XLPE insulation)

Nominal Voltages:U0/U 6/10 kV, 12/20 kV, 18/30 kV

Technical Data

| Single Core Cable(N2XSY)-12/20KV | ||||||||

| No. of cores and nominal cross section | Copper Wire Screen | Thickness of Insulation | Thickness of sheath | Approx. Overall Diameter (min-max) | Approx. Weight | Max. DC Resistance of conductor(20℃) | Current Carrying Capacity | |

| mm2 | mm² | mm | mm | mm | kg/km | Ω/km | in air(A) | in ground(A) |

| 1x35 | 16 | 5.5 | 1.8 | 27-32 | 1110 | 0.524 | 182 | 161 |

| 1x50 | 16 | 5.5 | 1.8 | 28-33 | 1250 | 0.387 | 215 | 188 |

| 1x70 | 16 | 5.5 | 1.8 | 30-35 | 1510 | 0.268 | 267 | 230 |

| 1x95 | 16 | 5.5 | 1.9 | 31-36 | 1780 | 0.193 | 325 | 274 |

| 1x120 | 16 | 5.5 | 1.9 | 32-38 | 2070 | 0.153 | 375 | 310 |

| 1x150 | 16 | 5.5 | 2.0 | 33-39 | 2310 | 0.124 | 421 | 342 |

| 1x150 | 25 | 5.5 | 2.0 | 33-39 | 2420 | 0.124 | 421 | 342 |

| 1x185 | 16 | 5.5 | 2.0 | 35-41 | 2650 | 0.0991 | 480 | 384 |

| 1x185 | 25 | 5.5 | 2.0 | 35-41 | 2810 | 0.0991 | 480 | 384 |

| 1x240 | 16 | 5.5 | 2.1 | 38-44 | 3260 | 0.0754 | 564 | 441 |

| 1x240 | 25 | 5.5 | 2.1 | 38-44 | 3360 | 0.0754 | 564 | 441 |

| 1x300 | 25 | 5.5 | 2.1 | 40-46 | 4020 | 0.060 | 645 | 495 |

| 1x400 | 35 | 5.5 | 2.2 | 43-49 | 4930 | 0.047 | 717 | 531 |

| 1x500 | 35 | 5.5 | 2.3 | 46-52 | 6050 | 0.0366 | 811 | 585 |

| 1x630 | 35 | 5.5 | 2.4 | 47-53 | 7510 | 0.0283 | 913 | 641 |

| Single Core Cable(N2XSY)-18/30KV | ||||||||

| No. of cores and nominal cross section | Copper Wire Screen | Thickness of Insulation | Thickness of sheath | Approx. Overall Diameter (min-max) | Approx. Weight | Max. DC Resistance of conductor(20℃) | Current Carrying Capacity | |

| mm2 | mm² | mm | mm | mm | kg/km | Ω/km | in air(A) | in ground(A) |

| 1x50 | 16 | 8.0 | 1.9 | 32-38 | 1480 | 0.387 | 215 | 188 |

| 1x70 | 16 | 8.0 | 2.0 | 34-40 | 1730 | 0.268 | 267 | 230 |

| 1x95 | 16 | 8.0 | 2.1 | 35-41 | 2060 | 0.193 | 325 | 274 |

| 1x120 | 16 | 8.0 | 2.1 | 37-43 | 2330 | 0.153 | 375 | 310 |

| 1x150 | 25 | 8.0 | 2.1 | 38-44 | 2720 | 0.124 | 421 | 342 |

| 1x185 | 25 | 8.0 | 2.2 | 40-46 | 3100 | 0.0991 | 480 | 384 |

| 1x240 | 25 | 8.0 | 2.3 | 42-48 | 3730 | 0.0754 | 564 | 441 |

| 1x300 | 25 | 8.0 | 2.3 | 45-51 | 4000 | 0.060 | 645 | 495 |

| 1x400 | 35 | 8.0 | 2.5 | 48-54 | 5330 | 0.047 | 717 | 531 |

| 1x500 | 35 | 8.0 | 2.5 | 51-57 | 6480 | 0.0366 | 811 | 585 |

| 1x630 | 35 | 8.0 | 2.7 | 52-59 | 7970 | 0.0283 | 913 | 641 |

The N2XSY and N2XS2Y are single-core medium voltage power cables designed for demanding industrial and utility applications. These cables feature a stranded copper conductor, XLPE (cross-linked polyethylene) insulation, and a dual-layer metallic screen (copper wire + intermittent copper tape), ensuring high reliability and resistance to partial discharges.

N2XSY: PVC (Polyvinyl Chloride) outer sheath.

N2XS2Y: PE (Polyethylene) outer sheath, ideal for low-temperature environments (-20°C).

1. The cable uses Class 2 stranded copper conductors in compliance with IEC 60228, ensuring excellent conductivity and mechanical strength. XLPE insulation provides low dielectric loss and high thermal stability for continuous operation in medium-voltage networks. The combination of stranded conductors and insulation ensures resistance to vibration, bending, and mechanical stress during installation and service.

2. Flame-retardant design with semi-conducting insulation layers and copper wire screen reduces fire propagation risk. The cable meets IEC 60332-1 standards for flame propagation and maintains integrity during short-circuit events. Optional LSZH (Low Smoke Zero Halogen) outer sheath provides additional safety in enclosed environments by minimizing toxic smoke emission.

3. Designed for installation in cable trays, conduits, ducts, and direct burial. Minimum bending radius is 15 times the overall cable diameter, allowing safe routing through complex industrial and urban network layouts. Stranded conductors and semi-conducting insulation facilitate easy manipulation without compromising electrical performance.

4. Available in 6/10 (12), 12/20 (24), and 18/30 (36) kV ratings. Continuous operation is rated up to 90 °C for XLPE-insulated cables, with short-circuit tolerance up to 250 °C for 5 seconds. Installation temperature down to -5 °C allows use in cold climates without risk of insulation cracking.

5. Conductor sizes range from 16 mm² up to 630 mm², with outer sheathing in PVC, FR-PVC, or LSZH as required. Cable length, color coding, and packaging can be adjusted to meet project-specific specifications. Optional copper tape or wire screen configurations provide enhanced electrical performance and shielding.

1. Power Distribution Networks – Medium-voltage transmission in urban and industrial networks, ensuring stable and reliable electricity supply.

2. Transformer Stations and Switching Blocks – Connecting transformers, switchgear, and control panels with high mechanical and electrical reliability.

3. Industrial Plants – Suitable for power supply in factories and processing plants, supporting machinery and automated systems.

4. Renewable Energy Projects – Efficient transmission for solar farms, wind farms, and hybrid energy facilities.

5. Complex Laying Environments – Ideal for underground or outdoor installations, cable ducts, and tight bends due to excellent flexibility, mechanical strength, and bending performance.

1. With over 20 years of experience in manufacturing medium-voltage cables, we understand the technical and safety requirements of complex power transmission projects.

2. 100% inspection of electrical, mechanical, and insulation performance to ensure reliability in demanding environments. Our quality system complies with international standards such as IEC and ISO.

3. We offer flexible customization for conductor size, insulation material, sheath type, and cable length. This allows our cables to meet the exact specifications of different industries including utilities, renewable energy, and heavy industry.

4. Our engineering team provides guidance from cable selection to project planning and installation. Customers benefit from technical documents, design recommendations, and on-site assistance when needed.

5. Our cables are designed to perform consistently under challenging conditions such as high load cycles, outdoor exposure, or underground installation, reducing downtime and maintenance costs.