- Home

- Products

- Certificates

- Cooperation

- About Us

- News

- Contact

Contact

+86 188 3213 4509

Contact

+86 188 3213 4509

Jul. 11, 2025

Electrical cables are critical components in power transmission and distribution systems, and their longevity directly impacts operational safety and cost efficiency. Three fundamental pillars govern cable lifespan: material science, environmental control, and proactive maintenance. Implementing the following strategies can significantly enhance durability:

1. Prevent Physical Damage

●Mechanical Stress Mitigation:

Avoid excessive pulling, bending (maintain bend radius >10×cable diameter), or crushing during installation. These actions accelerate insulation cracks and conductor fatigue. For underground applications, use HDPE conduits to protect against rodent bites and soil pressure.

●Industrial Solution: Deploy cable trays or ladders to organize pathways, reducing friction and abrasion. In high-traffic areas, reinforce with steel armor or nylon sleeves.

2. Combat Environmental Threats

●Moisture Resistance:

Seal cable terminations with heat-shrink sleeves or gel-filled connectors (e.g., 3M Cold Shrink). In humid environments (>60% RH), opt for IP67-rated junction boxes.

●UV/Heat Protection:

Outdoor cables require carbon-black polyethylene jackets for UV resistance. Install shade structures or reflective coatings to limit ambient temperatures to ≤60°C, as thermal aging doubles per 10°C rise.

3. Electrical Management

●Load Capacity Compliance:

Adhere to ampacity ratings (e.g., 16A max for 2.5mm² copper). Overloading generates heat, degrading insulation faster.

●Surge Suppression:

Integrate TVS diodes or MOVs to absorb voltage spikes (>1kV), especially in lightning-prone areas.

4. Inspection & Maintenance

●Residential:

Biannually inspect for discoloration, stiffness, or brittleness—key signs of aging. Replace if insulation resistance falls below 1 MΩ.

●Industrial:

Use infrared thermography to detect hotspots (>5°C above ambient) and partial discharge tests to identify microscopic insulation defects.

5. Quality Assurance

●Material Selection:

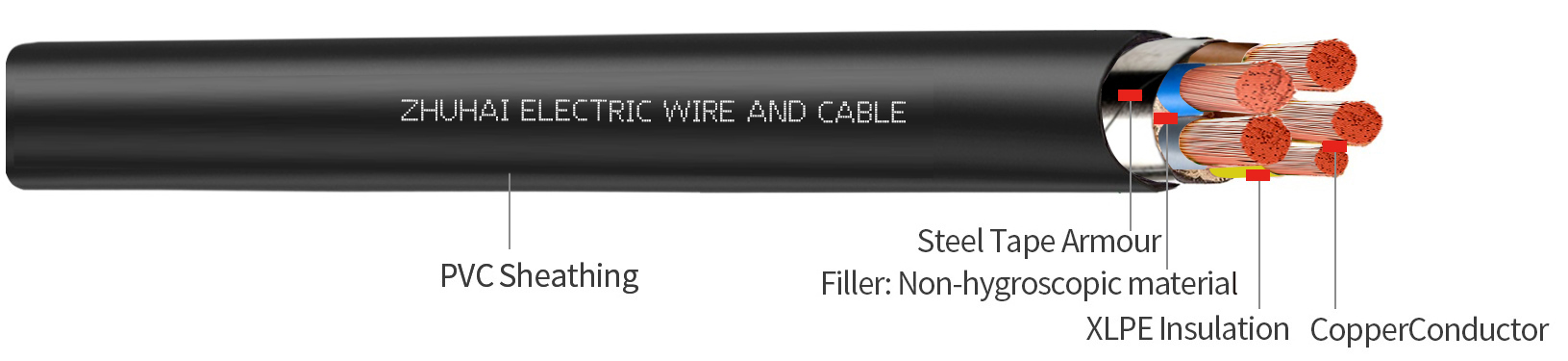

Choose XLPE-insulated cables (40+ years) over PVC (25 years). Verify compliance with IEC 60502 (industrial) or GB/T 5023 (residential).

●Case Study: ZhuhaiCable:

Their cables achieve extended lifespan through:

✅ Standards-compliant production (IEC/GB/T)

✅ Pre-shipment testing (insulation resistance >1 MΩ/km, 100% continuity checks)

✅ Environmental adaptations (UV-resistant, waterproof designs for coastal areas).

Pro Tip: In extreme environments (e.g., offshore wind farms), combine cathodic protection (for buried sections) with annual dielectric testing to target 60-year service life.

By systematically applying these measures, cable lifespan can exceed design expectations by 30–50%, minimizing replacement costs and unplanned downtime. For tailored solutions, consult experts based on your specific needs (industrial/residential),contact Tel/WhatsApp/weChat: 0086 18832134509 or Email: catherine@zhuhaicable.com